Systems & Products / Water and Wastewater Treatment / Odor Control with Biofiltration

- MBR Units

- Wastewater Treatment system for Boats (Electrocatalytic)

- Sea Water Treatment Systems

- Brackish Water Treatment Systems

- Renewable Energy Systems

- Penstocks

- Desalination Units

- Belt Conveyors

- Screw Conveyors

- Power & Free Conveyors

- Sand Classifiers

- Grab Bar Screen

- Rope Type Screen

- Stair Type Screen

- Rotating Helix Screen

- Helix Press

- Screen Screw Compactor

- Hydraulic Press

- Submersible Mixers

- Vertical Mixers

- Waste Containers

- Linear Sand Chambers

- Compact Sieve & Sand Chambers

- Air Distributor and Diffusers

- Circular Wastewater Settling Tanks

- Linear Wastewater Settling Tanks

- Water Treatment Settling Tanks

- Odor Control Systems

- Odor Control with Ozone

- Utilization Water Ozonisation

- Active Carbon Water Treatment

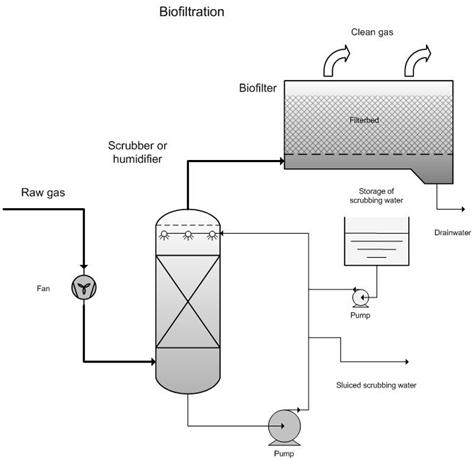

Biofilter Process for Odor Control

- System elements

- Fan

- Humidifier (FRP casing)

- Water heating system

- Water circulation pump and circuit

- Biofilter

- Biofilter media

- Biofilter raw gas transition grid

- Biofilter casing (To be done by buyer in case of reinforced concrete.)

Process description

In a biofilter the to-be-cleaned gas stream is passed upwards through a filter bed, which has been constructed of biological material, for example, compost, tree bark or peat. The filter material carries a thin film of water which is home to micro-organisms. The pollutants in the gas stream are retained in the filter material via adsorption and absorption, and are then decomposed by the present micro-organisms. The filter material serves as a supplier of necessary nutrients. The degradation products for conversion are carbon dioxide, sulphate, nitrate etc.The dry matter content in the filter typically varies between 40 to 60%. To prevent the bed from drying-out, the gas stream must be fairly well saturated with water. This is why to-be-treated air is normally moistened in advance. This can be done with a pre-implemented scrubber. The gas must have a relative humidity of 95%. In practice, it is always better to implement a humidifier in advance, in order to prevent the filter from drying out.

The filter material naturally contains enough different types of micro-organisms to deal with easily-degradable substances. In case of substances that are more difficult to degrade, the filter can be injected with special cultures in order to realise faster filter start-up, though close follow-up is essential to safeguard correct working parameters. The addition of minerals and nutrients may be desired if there is insufficient nutrient-release in the filter material.

Mixes of easy to degrade and difficult to degrade substances are difficult to break down in a biofilter because, first and foremost, the easily degradable substances are broken down, while the more complex substances are left behind.

During the design of the biofilter, the required bed volume is calculated via the breakdown rate of components in the flue gas. If the bed height is know (normally 1 -1.5m), then the required biofilter surface can be calculated. The biofilter can be customised on-site or can be purchased in pre-set modules. Depending on the load and the flow rate, multiple modules can be placed next to one another. The typical surface load for a biofilter amounts to 50 - 300 m³/m²h, but can be as low as 5 and as high as 500 m³/m²h. In biofiltration it is important for the filter material to have a pH between 7 and 8 for the break-down of organic components. The break-down speed reduces quickly at pHs less than 6.5.

Classic biofilters The residence time for the gas in the filter must be at least 30 - 45 seconds in order to effectively realise odour and solvent removal. Advanced Biofilters required residence time lies between 18-30 seconds.

When the packing is being introduced, one must ensure that the filter material is well distributed and that there are no solid of loose zones. These could lead to open streams, causing sub-standard air treatment and reducing the effective filter surface. The filter dries out quicker at the places where there is favourable air passage, which again reinforces this effect. If the filter material is systematically loaded with trucks at one side, this can easily create difficult-to-permeate zones and zones that are easy to permeate, which will quickly cause the biofilter to perform poorly.

It is necessary to closely follow-up filter operation so that one can react quickly when there is a reduction in the filter material's efficiency.

Open or closed

The biofilter can be open or closed at the top. In an open biofilter, the biofilter will be subject to rain, sun, moisture This may cause plant growth; after excessive rain, the biofilter could be too wet; after sunny periods the biofilter may be too dry. A closed biofilter is better protected against external weather conditions and can be better managed and followed-up.

Type of filter material

Depending on availability and the requirements of the biofilter, it is possible to amend the composition of the biofilter material. Here are some examples of filter materials: compost, tree bark, heath, peat, burr, coconut material, expanded materials Each of these filling materials has its specific properties in terms of specific surface area, stability and life-span, resistance against acidification and air resistance. It is also possible to implement a combination of materials. In order to avoid acidification, one could add buffering materials, such as lime and dolomite, to the filling material.

A chemical scrubber is sometimes used to remove acidifying components before the biofilter is implemented. These acidifying components include ammonia, amines, sulphur components, chlorides The scrubber acts as a pre-treatment and the biofilter ensures further degradation of the pollutants.

Removal of odoriferous substances in the wastewater area by biodegradation occurs according to the following equation.

VOCs + H2S + NH3 + O2 CO2 + H2O + Nitrates + sulphates

VOCs : Volatile organic compounds

H2S : Hydrogen Sulfide

NH3 : Ammonia

CO2 : Carbon dioxide

H2O : Water

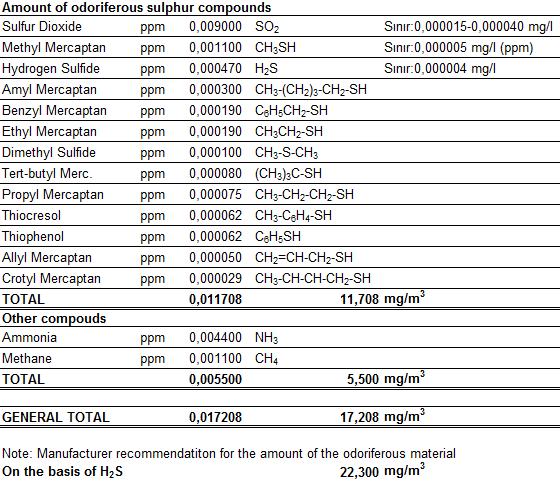

Our company makes biofilter process calculations and the amounts of all odor compounds on the basis of Hydrogen Sulfur.

TÜRKÇE

TÜRKÇE